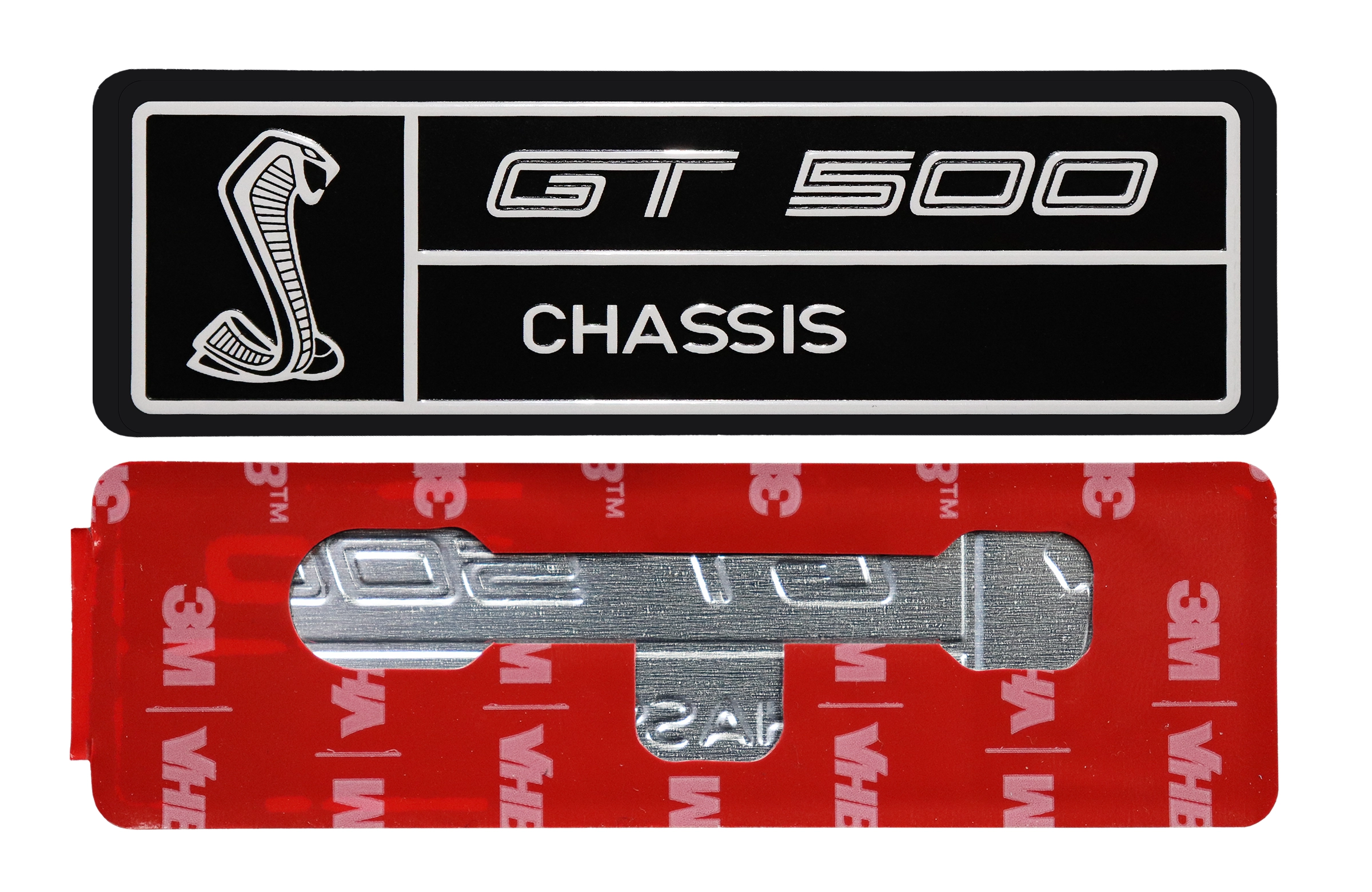

McLoone manufactures nameplates, labels, overlays, emblems, and badges for a variety of industries and consumer products. We provide busy customers with an easy way to order quality, durable graphics to brand products and provide critical information.

Whether you need an aluminum nameplate or plastic decal to differentiate your product or be a durable representation of your brand, our team has the expertise to give you exactly want you need when you need it.

The customization options are practically limitless with pressure-sensitive labels and metal plates. As your product identification partner, we’ll work to understand your product needs to design a perfect label solution.

We offer a large variety of adhesives for all surface types. Adhesive recommendations are made based on the type of substrate your nameplate is applied to and specifications the bond needs to meet. We can help with recommendations.

Yes, we also offer alternative adhesives. We can provide you with technical data sheets to support our recommendations. You make the choice which meets your needs and budget.

Yes, selective adhesive is a good option for overlays with windows or buttons and nameplates with formed edges.

Slitting the adhesive liner is a very effective way to make removing the adhesive liner a breeze. Another option is to supply parts in a strip with multiple parts allowing individual parts to be easily removed from the adhesive liner.

McLoone offers many types and thicknesses of foam adhesive for those situations requiring it. Sometimes textured surfaces, uneven surfaces, or slightly curved surfaces necessitate a foam adhesive for strong adhesion.

Preferred file formats are Adobe Illustrator CC (.ai, .eps, .ps, .pdf) and Photoshop CC (.psd).

For the best results and to minimize delays with your order, send electronic vector-based files. See our Artwork Guidelines page for more details.

Either call out your PMS, Pantone Matching System, colors separately or embed them into your electronic file. We can also match your supplied color swatch or physical sample.

Our experienced designers can convert your art to a vector format or create a high-quality art file. There is a standard $100 fee for this service.

Embossing is the process of raising graphics up above the original surface. It’s opposite, debossing, is used to depress graphics below the surface.

A minimum of .010”-.015” width on .020” aluminum depending on the type of tooling used.

Blind embossing is the term used to describe embossing that has no color contrast between the graphic and the background. It is popular in industrial applications and often used to create a premium look.

Yes, we have an extensive library of stock dies available in a wide variety of shapes and sizes. In addition, short run batches of small labels or large decals can be digitally cut eliminating all tooling costs.

Yes, we use screen printing and digital printing to print graphics and will choose the best option for your unique application.

McLoone custom matches to PMS colors or your color chips.

Yes, we do. Colors can be customized with matte or gloss finishes and fine or course textures.

In addition to standard opaque colors, many colors can be translated into transparent tints of color which are translucent and allow the reflective character of the metal to shine through.

Yes, a fine metallic sandblast finish is available to be integrated into the background or graphics of your nameplate, badge, or emblem.

Standard options are bright, mill finish, and brushed metal finishes.

Yes, we do. Carbon fiber finishes are one of our most popular finishes used in nameplate design. They are often featured in premium products and can be customized to your application.

Yes, our designers can work with you to create a unique finish or customize an existing pattern on aluminum to meet your application needs. We have a pattern library with finishes to choose from. All can be adjusted in color, size, and design to meet your requirements.

Factors in choosing the substrate to satisfy branding needs vary from product to product. These include budget, design intent, life span, and regulatory requirements specific to the market for the product. Standard substrate options for product identification include aluminum, brass, stainless steel, polycarbonate, polyester, and vinyl. Other materials can be reviewed as needed. Our team can help with recommendations.

We use screen printing and digital printing on a wide variety of metal and flexible materials. Versatility in decorating options for metal and plastic substrates gives you the opportunity to design unique branding components integrated into your final product.

Our standard metal substrate for nameplates is aluminum. We can simulate the look of most metals including copper, brass, and stainless steel on aluminum. If your application requires brass, stainless steel, or anodized aluminum, we also work with these materials.

Yes! We offer custom domed labels in any size or shape as an attractive option for adding dimension to aluminum and polyester labels. Domed labels feature superior durability and vibrant color.

Our typical turnaround on the production floor is 7-10 days. Lead time starts with placement of the order including all required specifications and approval of your artwork proof.

McLoone ships globally to customers in Canada, Mexico, Europe, and Asia.

Yes, we have samples of nameplates and labels using a variety of processes and substrates for your reference. Request samples here.

Yes, we supply electronic proofs prior to production for all parts. For projects requiring further review prior to full production, pre-production samples and protypes can be quoted.

McLoone custom manufacture nameplates and labels and we do not have “stock” items.

No, there is not a minimum order requirement. We process orders ranging from 1 to 100,000 pieces. All are custom manufactured to meet your specifications and delivery needs.

Certainly, we provide choices for labeling and branding assets using vibrant and long-lasting custom metal equipment nameplates featuring stamped sequential numbering. In addition, digitally printed labels with variable data, allow for the customization of text, barcodes, QR codes, or images on each individual label.

McLoone manufacturers durable nameplates and badges for a variety of industries and consumer products used in outdoor applications.

We stand by our products 100%, no matter what. If you have a problem, we will solve it. Whatever it takes! Just reach out to our Customer Care Team. We're here for you. Quality. Guaranteed.

Our metal and plastic nameplates are manufactured in an ISO 9001:2015 certified manufacturing operation. We are RoHS compliant and are an authorized UL label supplier.

75 Sumner Street, La Crosse, WI 54603

1-800-624-6641 info@mcloone.com